slabs and hollow core slabs

Prefabricated hollow core slabs were usually precast in reinforced or pre-stressed concrete. They often had a rectangular or trapezoidal cross section, and continuous, longitudinal cavities. While the top and bottom of the slab had a structural and practical function, the inner mass could be hollowed without any loss of function, yet this reduced the slab’s weight substantially. The hollow cores could be created in different ways, for example, by using metal moulds that were retracted after hardening, or by extrusion (without internal formwork) if a very dry concrete mixture was used. The long edges of the slabs were often chamfered to allow a reinforcement bar to be inserted in the joint. Hollow core slabs were made in different sizes, ranging from 25 cm to 160 cm wide (commonly between 40 and 60 cm), and usually up to 4 m or even 8 m in length.

This became a very popular building product, and consequently several manufacturers produced hollow core slabs for the Belgian market. Some of these companies were construction companies that used their own hollow core slabs in construction works, while others were mainly manufacturers of building materials. During the 1950s and 1960s, in an effort to stand out in this abundance, many manufacturers focused on particular characteristics, e.g. producing elements with shorter lengths or smaller weights (both to ease the installation) or using specific types of concrete for higher loadbearing or thermal insulating capacities. In the 1970s, attempting to normalize and standardize the prefabricated floor systems that had proliferated since the end of the Second World War, the Federation of the Precast Concrete Industry in Belgium (Febe, the successor of the Union for Agglomerates with Cement of Belgium UACB) edited a brochure on the standardization of precast concrete elements for buildings. One of the things put forward in the brochure was a standard width of 60 cm or 1.20 m for hollow core slabs. The preferred thickness was between 15 and 40 cm, with regular intervals of 5 cm.

lighter – shorter – stronger

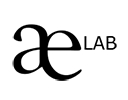

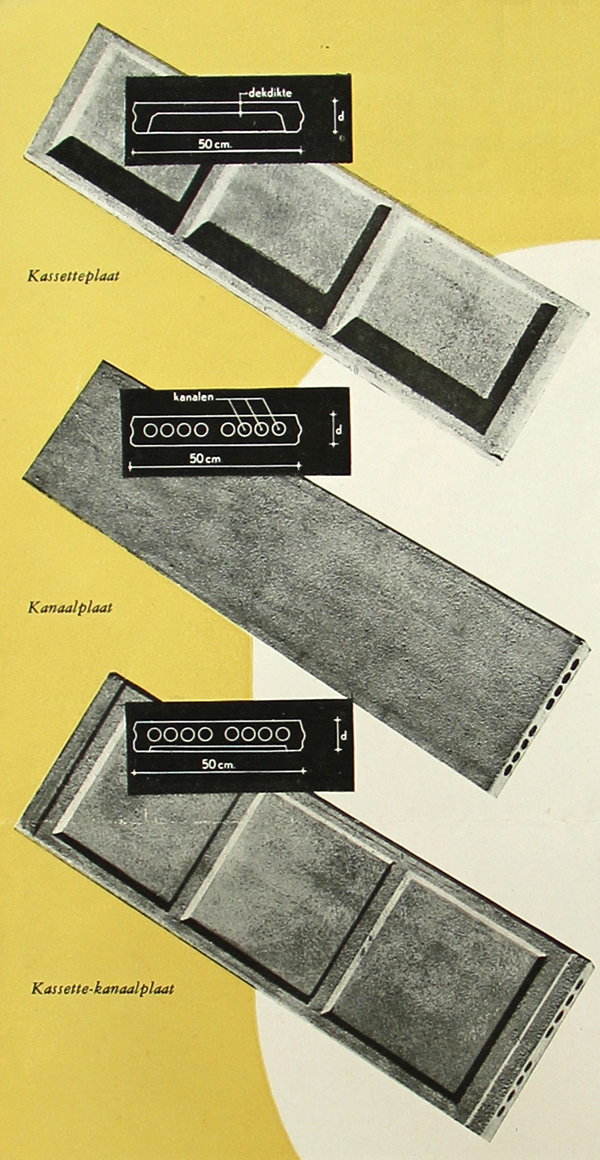

To enhance the appeal for their products for certain applications, manufacturers reduced the weight and improved the thermal capacity of their hollow core slabs. Several manufacturers used particular types of concrete, for instance concrete with pumice or other lightweight aggregates. Pumecrete was used by Bims d’Origine in rather typical hollow core slabs. The Dutch company Schokbeton and Westvlaamsche Betonwerkerij were more creative. Schokbeton, for instance, produced three types of hollow core slabs in pumecrete: regular hollow core slabs, a cassette floor, and a type that combined these two types. The cassette floors had large, square hollows or alcoves on the bottom side. They were lightweight, while the longitudinal and transverse ribs of the cassettes provided loadbearing strength and ensured the rigidity of the slabs. Although its thermal insulation capacity was slightly lower than that of hollow core slabs, these floors generally weighed less. Schokbeton also combined the two concepts in a slab having both a series of continuous, longitudinal cavities at the top and shallower square alcoves at the bottom. All three types were 50 cm wide with a maximum length of 3.70 m, and had a tongue and groove joint at the side. Depending on the expected loads (between 200 and 500 kg/m²), the slabs were 7 to 13 cm thick.

Westvlaamsche Betonwerkerij also used pumice concrete for their hollow floors Solidus, yet in a very particular way. They created a hollow element in lightweight pumecrete (between 900 and 1000 kg/m³), which was shaped like a circle segment with a central stiffening rib. The top of this hollow element was covered with a heavier type of pumecrete (up to 1300 kg/m³), including reinforcement, to form a rectangular shaped slab. The edges had indentations to improve adherence of the joint mortar. Because of the combination of hollow cores and lightweight aggregates, these slabs weighed up to 60% less than solid concrete floors.

The Belgian company Echo (founded in 1950 by Eduard Cuyvers in Houthalen, hence the acronym ECHO) used washed and calibrated schist as aggregate to reduce the weight of their precast concrete products. They produced hollow core slabs up to 4.50 m long, which were ideally suited for houses and apartments. As the company and the technology evolved during the 1960s and 1970s, Echo expanded its product range with hollow core slabs made of reinforced and pre-stressed concrete.

Another manufacturer in this category is the Belgian company Isobeton, which produced blocks, slabs, and entire houses in ‘insulating concrete’ (the exact composition of which was not published though). The Isobeton precast slabs were 40 cm wide, 12 cm high, and up to 4 m long. They weighed 50 kg/m², could carry 250 kg/m², and had a λ-value of 0.87 W/mK.

Another way in which the range of hollow core products was diversified, was by producing short elements, which were easier to transport and to install. An example of these was the hollow core slab Ultra produced by Gelderbeton. Similar to standard hollow core slabs, Ultra had longitudinal reinforcement and stirrups in the joints, and a compression layer with transverse reinforcement on top. But unlike standard slabs, these reached only half-way across a span. To connect the half-way slabs, a 10 cm transverse rib was cast in situ, requiring temporary struts and formwork. A maximum total span of 8 m could be achieved.

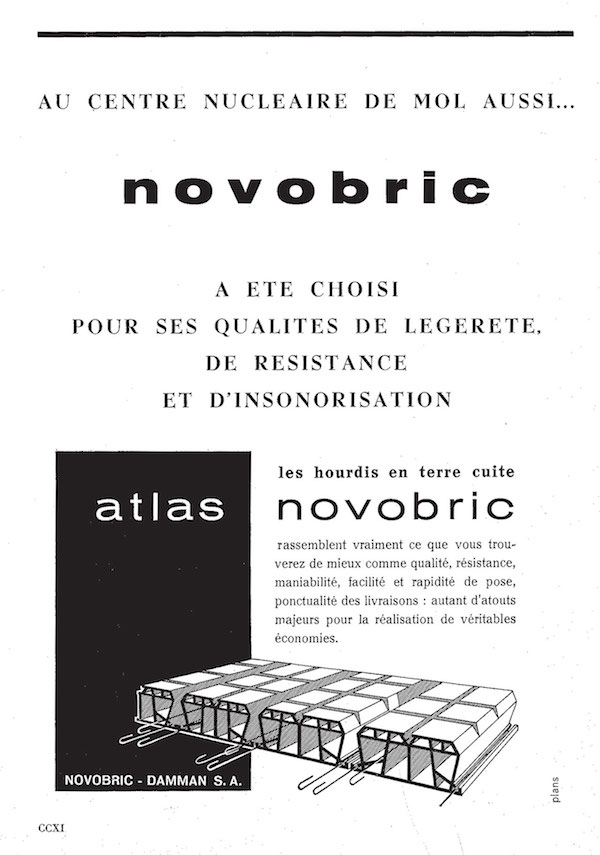

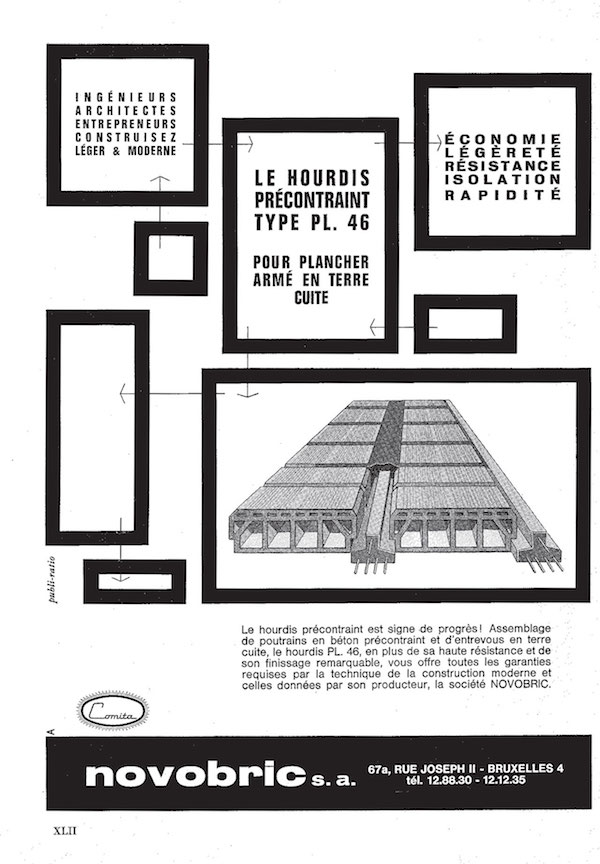

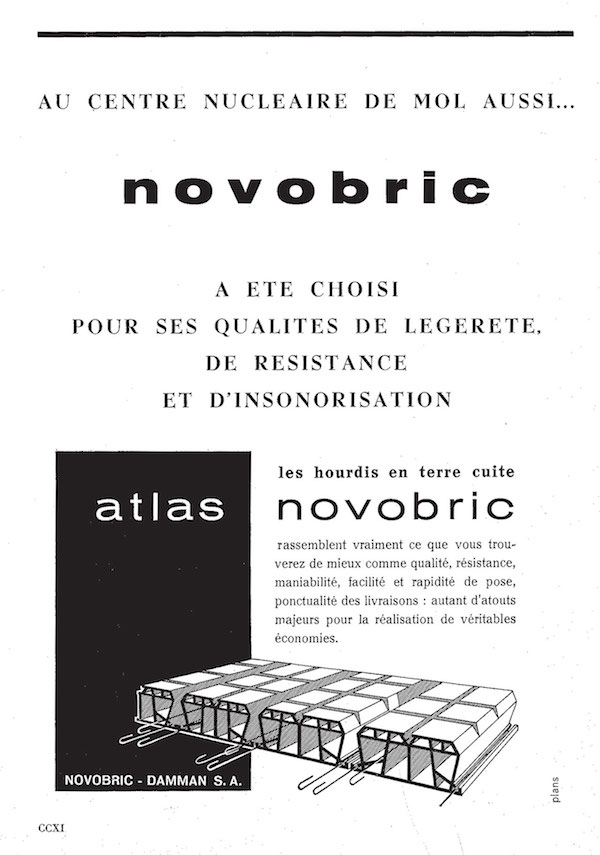

Another manufacturer of shorter elements was the Belgian company Novobric. They designed several floor systems, for instance the hollow floor slabs Excelsior: these 25 cm-wide slabs were very short (between 1 and 1.6 m) and thin (4 or 6 cm high), and did not need to be covered with concrete. Because of the small dimensions and limited loadbearing capacity, these slabs or panels were suited for short spans or to cover roofs.

The loadbearing capacity of hollow core slabs could be increased by using specific compositions of reinforced concrete, special configurations of the reinforcement, or pre-stressed concrete.

The company Matériaux et Techniques Modernes M.T.M., with a factory in Machelen, produced three different types of self-supporting hollow core slabs in vibrated concrete (P1, P2, and P3). All three looked the same on the outside and had three circular, longitudinal cavities inside. Yet by varying the exact composition of the concrete (e.g. changing the cement quantity), the three types could support different maximum loads (up to 500 kg/m²) and achieve spans up to 4.80 m. In addition, M.T.M. produced a hollow core slab named ‘N’: this had a different edge profile so that less concrete or mortar was needed to fill the joints.

An example of a hollow core slab with specific reinforcement was Ultra by Vibrabeton. It was reinforced in two directions: longitudinal reinforcement at the bottom of the slab and transverse reinforcement at the top of the slab. The transverse reinforcement protruded approximately 40 cm so that the bars could be connected and form a continuous reinforcement. The Ultra slabs came in three types: 11 cm high (30 cm to 3.80 m long, weighing 75 kg/m²), 15 cm high (30 cm to 3 m long, weighing 105 kg/m²), and 20 cm high (30 cm to 2.60 m long, weighing 125 kg/m²).

Probably the most efficient way to enhance loadbearing capacities of these elements was to make them with pre-stressed concrete. One of the major Belgian manufacturers of precast and pre-stressed concrete products was Ergon in Lier. Ergon was founded in 1963 as a subdivision of the cement manufacturer CBR (Cimenteries et Briqueteries Réunies) for precast cement and concrete products. Ergon mass produced beams, columns, panels, TT-floor slabs, and hollow core slabs, made of reinforced concrete and pre-stressed concrete. Compared to the hollow core slabs in reinforced concrete, which were 60 cm wide and up to 6m long, the pre-stressed concrete floor slabs usually were wider and longer. An example of the latter is the Ergon SP-floor slab. Both the top and the bottom surfaces of the 1.20 m wide floor slab were flat, and it had circular cavities running through its length. The thickness of the slab (20, 27, or 32 cm), and the number of pre-stressing cables, were determined by the desired loadbearing capacity. The slabs were made by means of an extrusion process; after the concrete had set, the 80 m long slab (including the pre-stressing wires) was cut into the desired lengths. Spans could vary from 6 to 14.5 m, and support a service load range of 2000 to 250 kg/m², respectively. The SP-floor slabs were mainly used for spans between 6 and 9 m.

special cross sections

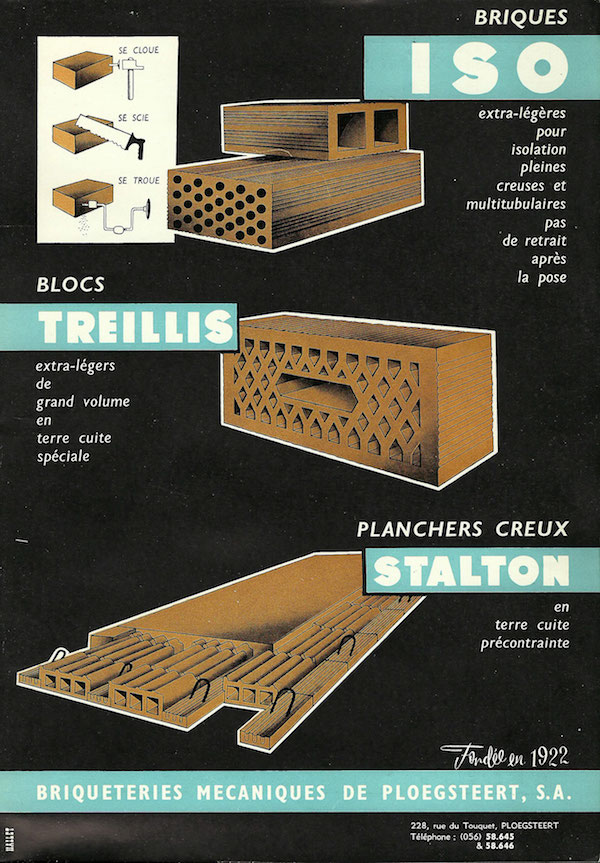

While most of the hollow core slabs had a more or less typical cross section (rectangular or chamfered, with a number of circular cavities inside), several companies developed hollow core slabs with special profiles. These included the Record slabs, manufactured by the company Briqueteries du Brabant, and the Zig-Zag slabs, manufactured by Scheerders van Kerchove (SVK). Another example of a hollow core slab with an intricate cross section was Atlas developed by Novobric. These elements were light and easy to handle, and had good insulation properties (λ-value of 0.145 W/mK). They consisted of short elements in ceramics that were connected lengthwise to create slabs, by means of reinforced concrete inserted in three small grooves at the cop of the ceramic elements. These slabs, which could be cast in situ or in the factory, were then put next to each other and the joints between them were filled with concrete. The maximum length of the Atlas slabs was 8 m (under a load of 250 kg/m²). Individual ceramic blocks had widths of between 25 or 33 cm, and heights of between 8.5 cm and 20.5 cm. An optional compression layer added 3 cm to the total height. Novobric used the same elements to produce wide, prefabricated slabs, delivered on site with a maximum length of 6.85 m.

Similar to the already mentioned cassette floor slabs by Schokbeton, were the cassette floor slabs made by Duyck in vibrated reinforced concrete. The patented profile of the slab, shaped like an inverted U, reduced the dead weight without comprising the slab’s rigidity. As they were ‘open’ at their extremities, Duyck provided special filler pieces to prevent concrete cast in situ at the supports from leaking. The slabs came in different forms and dimensions. The standard types 1 to 7 were either 14 or 17 cm thick, 40 cm wide, and spanned up to 5 or 6 m. The sides of the slabs were either chamfered or rectangular, and they weighed 125 or 155 kg/m². For long spans or heavy loads, the slabs could be combined with prefabricated, reinforced concrete ribs placed in the joint between two slabs (types 1R to 7R). This system eliminated wet mortar and in situ concrete, and resulted in an important savings in time and finishing cost, as the floor could be used immediately after installation. If necessary, a compression layer could be applied. The maximum spans were determined according to loads: for example, for type 7(R), the maximum span that could safely support 350 kg/m² was 6.40 m; this span dropped to 3.50 m for a load of up to 1000 kg/m². Duyck also produced types T1 and T2 (both with or without a precast rib). These were smaller than the standard slabs: they were only 12 cm thick, and intended for smaller spans (up to 5 m) and loads of 250 to 300 kg/m². T1 and T2 looked and weighed the same (115 kg/m²), but the extra reinforcement added to the latter, allowed a higher load.

Another particular type of hollow core slab was B.A.S.C., which stands for ‘Béton Armé Sans Coffrage’ (reinforced concrete without formwork). These were beams with a cross section shaped like a circle segment; in situ concrete was cast between them to create floors. The beams were hollow (except on their extremities), with two thickened corners at the bottom where a reinforcement bar was incorporated. The B.A.S.C. floor was developed in the interwar period and continued to evolve during the post-war period: in the 1950s, the type B.A.S.C. Minor was added to the existing Standard and Major types. The three types were based on the same concept, yet had different dimensions and performance measures. The smallest beams, type Minor, were 12 cm high, 33 cm wide, and up to 5 m long; they weighed 81 kg/m², without the filling concrete. Spanning 3.75 m, they could carry a load of 200 kg/m²; if the span was increased to 5 m, the load decreased to 150 kg/m². The Standard beam was 16 cm high, also 33 cm wide, and up to 6.50 m long, and weighed 90 kg/m². With a load of 350 kg/m², the maximum span was 4.50 m. The Major beams were 26 cm high, 40 cm wide, and 2.50 m long, and weighed 115 kg/m². These were always executed with a layer of reinforced concrete on top (while this was optional in the two other types), to carry maximum loads from 500 to 2000 kg/m², with spans over 6.5m. The bottom of the B.A.S.C. floor was usually rough, so it could be plastered directly.

The B.A.S.C. floors were advertised as being easy and quick to construct, economical, lightweight, fire resistant, acoustically insulating, insensible to chemical agents, rigid, and monolithic. Given the structural and formal design of the beams, the two latter properties demand a critical look. If the floor was not finished with a reinforced compression layer on top, the claim that it was monolithic is questionable. Secondly, the precast beams were very slender elements: the smallest beams were only 12 mm thick at the bottom and 22 mm at the somewhat thickened top, which raises questions about the loadbearing resistance of the beams, as well as the concrete cover of the reinforcements. Nevertheless, the B.A.S.C. floors were used on a relatively large scale: a 1950s commercial brochure mentions that over 80.000 m² of B.A.S.C. floors had been installed in apartment buildings, mostly in Brussels.

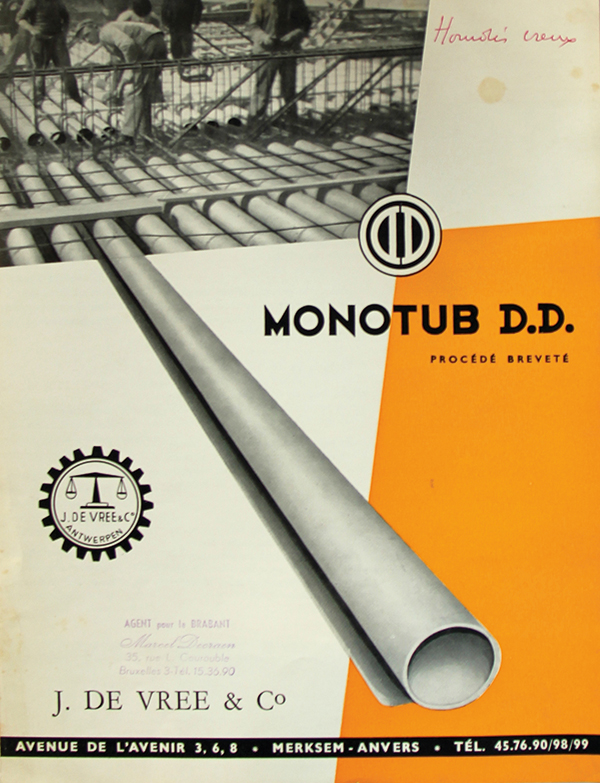

Monotub D.D. is another product that can be mentioned in the category of hollow core slabs. Monotub D.D. were hollow tubes made of waterproof cardboard which were used as internal, permanent formwork for hollow core slabs. The tubes were used to produce precast slabs and also on site, to make customized hollow floor slabs. Light and cheap, yet strong and moisture resistant, the tubes came in various diameters, from 5 to 50 cm, and were cut to the desired length at the factory or on site. During production, the tubes were held in place by connecting them to the reinforcements. The tubes increased a floor’s thermal capacity (up to 40%) and reduced its weight: depending on the thickness of the floor and the diameter of the tubes, the Monotub floor weighed 30 to 45% less than a solid concrete slab. For a floor of 15 cm, for example, this meant 125 kg/m² less dead weight.

solid slabs

Companies also reduced the weight of floors by making (solid) slabs with lightweight concrete. Matériaux et Techniques Modernes M.T.M. and Westvlaamsche Betonwerkerij produced both hollow core slabs and lightweight-concrete solid slabs. These solid slabs had relatively low maximum spans and loadbearing capacities (spans from 1 to 3 m and loads from 150 to 200 kg/m²): they were intended to be used mainly as roof decks or roof linings. Also, the Belgian company Fixolite produced self-supporting, reinforced solid slabs in lightweight concrete, to be used for roofs. These slabs were 6 to 16 cm thick, 50 cm wide, and 1.10 to 4.5 m long, and supported a load of 150 kg/m². The concrete used by Fixolite was based on mineralized wood fibers, mixed with cement. It weighed only 650 kg/m³ and had good acoustic and thermal properties (λ-value between 0.072 and 0.093 W/mK). Also other brands of lightweight concrete, including Argex, Durisol, Durox, Siporex, and Ytong, were used to make this type of slab, reinforced or not, for roofs, roof linings, and in some cases floors (see also chapter 1 on lightweight concrete).