import/export

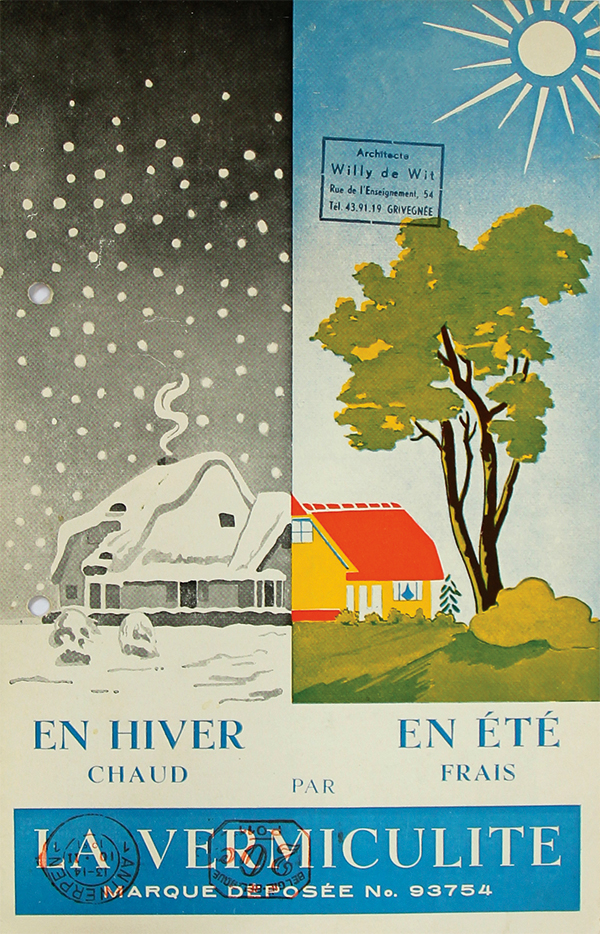

Given the diverse kinds and forms of insulation, many brands were available in the Belgian market. A number of these were Belgian (produced in Belgium by a Belgian company), while others were imported by large international companies, or produced in Belgium by local divisions of big multinationals. The synthetic insulation materials, in particular, were produced by international companies. Sparked by the introduction of synthetics, a number of Belgian companies that already produced mineral and vegetal insulation materials expanded their activities.

Belgian companies

One of the main Belgian insulation companies was Isoverbel. Short for Isolation de verre belge, Isoverbel produced thermal and acoustical insulation materials made from glass (glass wool, glass silk, and glass fibres). It formed in 1937 from the insulation department of the glass company Saint-Gobain. Isoverbel had a large research and consultancy department, and a production department with two factories in Franière and Namur. Their insulation products were rot-proof, fire resistant, and unaffected by moisture and micro-organisms, and they retained their insulating properties permanently. Glass fibre products existed in various forms: in bulk; sewn on cardboard mats or galvanised wire mesh; as sheets and blankets, possibly with bitumen paper covers; rigid plates and perforated panels; mixed in a finishing mortar, etc. The basic panel produced by Isoverbel, designed to insulate inner and outer walls and cavity walls, was Isover P.B., a semi-rigid glass fibre panel measuring 60 by 120 cm. By incorporating such a panel in a cavity wall, the thermal resistance of the wall would quadruple. These panels could be finished with a bituminous kraft paper on one side, which functioned as a vapour barrier. Another Isoverbel product was Rollisol: this was a blanket on a continuous roll, up to 12 m long, with a bituminous kraft paper on one side and a perforated kraft paper on the other side. It was used to insulate roofs. Thin sheets IBR were also sold on continuous rolls, with the option of bituminous kraft paper coverings. Roof panels called P.I. Roofing were very heavy and rigid with a layer of glass fibre-reinforced bitumen on top. Another type of rigid panel was Shedisol Alu plates: these had kraft paper or a layer of aluminium foil on one side, and were used in cellar floors or roofs of industrial buildings. Isoverbel’s product range was further expanded with panels P.I. 156, P.I. 256, P.I. 456, acoustic panels P.A. 305 and Bergla, Stryroverbel (expanded polystyrene), etc. As they had a large range of products, which were used in a very broad range of applications, Isoverbel developed many manuals and other kinds of documentation for their thermal and acoustical insulation products. For instance, they prepared a number of building specifications, each time indicating the appropriate product for a particular application, e.g. for the insulation of concrete floors with floating floor systems (Feutre-sol Isover), flat roofs (P.I. Roofing), external walls and cavity walls (Isover P.B. panels), and pitched roofs (Rollisol).

Isoverbel’s products were also sold by Cantillana, a building materials supplier founded in 1875 in Sint-Niklaas, which specialized in plaster and gypsum. Since 1933, Cantillana sold their own Cellulit board – panels made with wood fibres and gypsum, which were lightweight, insulating, and fire resistant. In addition, from the early 1950s onwards, Cantillana sold glass fibre products, including those made by Isoverbel; they claimed to be the “seul agent dépositaire pour le Grand-Bruxelles de la S.A. Isoverbel”. Their product range consisted mainly of glass wool (in bulk or blankets, whether stitched or not onto cardboard, kraft paper, or a galvanized trellis) and glass silk (in sheets and rolls). These could be used between a concrete floor and screed, and in lowered ceilings, walls, and flat and pitched roofs. Cantillana also created some added value by incorporating the standard Isover P.B. panel in an acoustic panel called Insona. These perforated finishing panels were made out of plaster with glass fibre reinforcement and measured from 30 by 30 cm to 62.5 by 62.5 cm, and up to 2 cm thick. To enhance the sound absorption, they were finished with a veil of glass silk Coromat and a semi-rigid Isover panel at least 2.5 cm thick. The Insona panels were fire resistant, form-retaining, and insensible to moisture and high temperature. The panels were attached by means of screws, either onto a lattice structure or onto a suspended ceiling structure.

The firm Société Belge Isolex was very similar to Isoverbel: it was also a consulting agency, as well as producer and installer of glass fibre insulation. The company produced both thermal and acoustical insulation, with a focus on the latter (sound absorption, vibration dampers, and reverberation reduction). It produced insulation in different forms, e.g. panels, plates, tiles, and spray-ons. Examples of Isolex products are Fiberglas Aerocor (blankets with bakelized glass fibres, insensible to water and fireproof), Navitex (a sound absorbing, porous fibreboard), Acoustifibre (wood fibreboard), Econacoustic (light wood fibreboard), Fiberglas Perforated Tile, Travacoustic (mineral fibreboards), Gold Bond Insulation Tiles & Planks (wood fibre tiles), Metal-Acoustic (perforated panels), Acousti-pan (flat perforated metal panels with a core of glass insulation), and Sprayed Limpet Asbestos S.L.A. Except for the latter, an asbestos spray, most of these products were based on wood fibres or glass fibres, in the form of boards or tiles. The tiles and boards were often finished with a porous or rough surface to improve sound absorption. Isolex marketed insulating cement mortars for use as screed (e.g. Matelas R.B.) or as ceiling finish. It also produced Isostyrene: white, hard panels of expanded polystyrene, weighing between 15 and 60 kg/m³ (λ = 0.031 W/mK). These could be nailed, sawn, and painted; they were insensible to acid and oil; and they were flammable. In addition, Isolex distributed the glass fibre sheets and panels made by the American company Owens-Corning Fiberglas to the Belgian market, from the 1960s onwards. These plates absorbed sounds (because of the millions of enclosed air bubbles). They were light; easy to transport and to place; rot-proof; inert and odourless; fire resistant; form-retaining; and finished in various, decorative ways (striped, perforated, textured). The Owens-Corning Fiberglas products, which can be recognized by their pink colour, were also distributed in Belgium by Eternit, another Belgian company that produced and distributed insulation products.

Eternit is known best for its asbestos products, which were used for insulation among other things (often mixed with cement or used in sandwich panels), yet Eternit actually had a broad range of (mainly mineral) insulation products. For instance, Eternit produced Eterglass, made with glass fibre wool that was ‘bakelized’ or impregnated with synthetic polymerized resins. Eterglass was fireproof, rot-proof, insensible to moisture, and available in different forms. These included Eterglass BL Kraft/Nu (sheets or blankets, with or without bituminous kraft paper), Rolliglas (with kraft paper on both sides), Sonosol (sound insulation blankets and boards), Type 700/701/702 (rigid and semi-rigid panels for walls), and Type 703/704 (rigid panels with a high density, mostly used in floors). In addition, during the 1960s, Eternit distributed a number of insulation products based on glass fibres manufactured by Owens-Corning Fiberglas, designed to insulate inner and outer walls, roofs, ceilings, and partition walls. All products, whether soft or rigid, incorporated glass fibres in different forms and qualities, e.g. sheets of polymerized spun glass fibres and glass fibre panels for false ceilings. The Owens-Corning Fiberglas ceiling panels (Sonocor, Sonoplat, and Sonoflex) were very similar to each other: they were put in place between metallic frames and were easy to lift or move afterwards, so pipes and ducts stayed accessible. The panels were low-maintenance, lightweight (0.85 kg/m²), and easy to clean with water and soap. As for thermal capacity, such a false ceiling would be equal to 25 cm of gas concrete or 108 cm of reinforced concrete. Acoustically, the panels performed very well, thanks to the air bubbles included in the mass of the glass fibre panels. Eternit also produced other insulation products like Menuiserite (a panel in asbestos cement with cellulose fibers), Lithoperl (expanded perlite), Eterfoam (an insulation foam based on an expanded phenol-formalin resin), and Glasal sandwich plates (with a core of polystyrene or Eterfoam). With this latter, Eternit extended their product range from mineral insulation materials to synthetic insulation materials. Isoverbel had done likewise, when the company started to produce the expanded polystyrene product Stryroverbel, following the success of the international manufacturers Dow and BASF at the end of the 1950s.